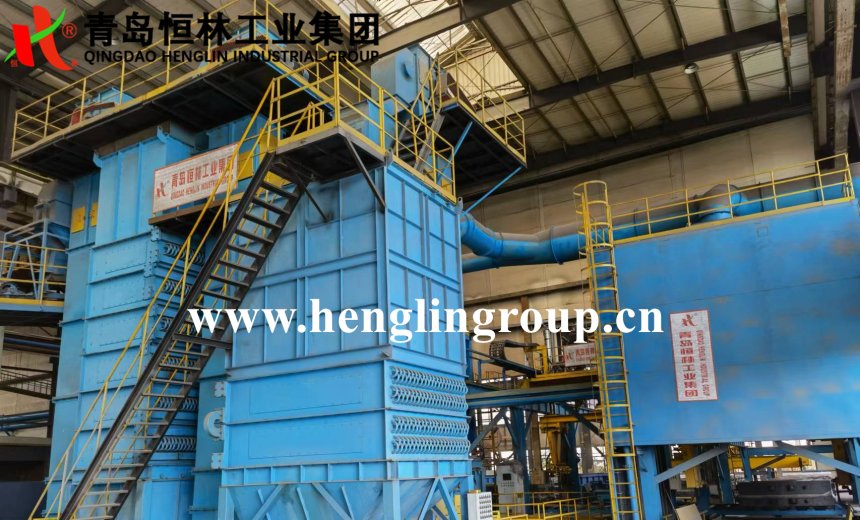

It is composed of sand conditioning system, molding system, vacuum control system, water control system, electrical control system, etc. The sand conditioning system is composed of old sand cooling and conveying equipment, dust collecting equipment, PLC system, etc. to realize the recycling of old sand; molding system is composed of flasks, mould lifting system,mobile vibrating table, etc. Equipped with flask turnover manipulator to form a molding line with high degree of automation. This process is a kind of environmental protection molding process, known as the "green revolution of the foundry industry".

China Supplier and manufacturer of V process / Vacuum Sand Casting Machine, Vacuum Molding Process Line

The principle of Vacuum Molding Line is the use of plastic film to seal the sand box, by using negative pressure vacuum pump to get the air out of the mold, to form pressure difference between the inside and outside of the mold. So that can make the dry sand compacted to form the desired cavity.

1. The biggest advantage: without using adhesives, thus reducing environmental pollution

2. The work load of sand cleaning on the castings has been greatly reduced

3. The recycling rate of old sand is more than 95%

4. Castings: good quality, smooth surface, clear outline, accurate size, even hardness

| Parts of Vacuum Sand Casting Line | Parameter and Introduction |

| Sand Conditioning | 10, 20, 30, 40, 50, 60 T per hour capacity, etc. |

| V Process Molding Station | vibrating table, film machine, sand adding, flask turnover manipulator etc. |

| Vacuum System | vacuum pump, vacuum tank, water pump, cooling tower, etc. |

| Dust collecting system | Pulsed bag or cartridge type dust collector |

Water control system

| Water pump, cooling tower, etc. |

Electrical control system

| PLC of Siemens, Touch Screen |

| Hydraulic System | Hydraulic pump, valves, pipe, etc. |

V process molding, vacuum casting, v-process casting equipment, v-process supplier, vacuum process manufacturer

Vacuum Process Casting is suitable for the simple structure and big castings, such as counterweight, railway bolster, bogie frame, axle, steel valve body, jaw crusher, cone crusher, steel track shoe(Sany Heavy Industry who manufacture this casting by our v process equipment) etc.